Mining Connectivity Solutions

Intermountain Technologies delivers mining connectivity solutions that help your team stay informed and responsive from the open pit to the deepest sections underground. As equipment becomes more autonomous and data-heavy, dependable wireless coverage is essential. Our mining technology solutions are built to adapt, scale and perform, even where traditional networks fall short.

At the center of our approach is Rajant’s Kinetic Mesh®, a fully mobile, real-time wireless network trusted in more than 300 mines worldwide. Unlike fixed LTE or fiber infrastructure, Kinetic Mesh® creates a living network that continually adjusts to the shape and behavior of your site. Every node communicates with every other node, providing consistent mining machine connectivity.

Open Pit Mining Technology Solutions

Surface mines change constantly as haul roads shift, benches expand and blast patterns evolve. Those changes demand open pit mining technology solutions capable of keeping up. Traditional towers often struggle with blind spots and handoff issues, especially when large equipment or terrain features interrupt line of sight.

Intermountain Technologies delivers a mesh network that moves with the mine. Your team can add, remove or relocate nodes quickly, allowing you to maintain strong and steady open pit mining connectivity through every phase of the operation, without downtime. The result is wider coverage, lower latency and consistent performance that supports fleet management, high-definition video, environmental monitoring, safe autonomous equipment operation and other real-time applications.

We recommend Rajant’s Sparrow, Peregrine, Hawk and Cowbell product families for open pit environments due to their rugged design and exceptional throughput.

Underground Mining Technology Solutions

Connectivity underground is uniquely challenging. Tunnels, walls and constantly shifting working faces can restrict wireless signals, limiting communication when crews need it most. Our underground mining technology solutions are built specifically for these environments, providing high-speed, multi-radio wireless coverage where voice-only systems often fall short.

With Rajant’s autonomous V2X and machine-to-machine networking, data passes across the mine without relying on fixed infrastructure. Teams receive reliable underground mining connectivity that supports safety systems, ventilation monitoring, equipment diagnostics and critical voice and data communications right at the working face.

Solutions such as the REIOS sTRACK, Peregrine, Cardinal, and Cowbell nodes deliver rugged performance in tight and demanding spaces.

Mining Machine Connectivity

Today’s equipment generates essential data, including engine health, tire performance, payload accuracy and location details. Mining machine connectivity is what turns that raw data into real value.

Intermountain Technologies’ approach ensures that your machines remain connected no matter where they operate. With fewer interruptions and no handoff delays, operators maintain continuous communication with dispatch, maintenance and safety personnel. This creates a smoother workflow and a safer working environment for every shift.

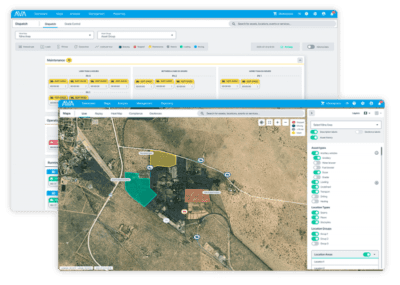

AVA Software Solutions for Cycle Optimization

To help mines improve production flow and reduce operational delays, IMT offers AVA — an advanced software platform designed for cycle optimization, fleet visibility and short interval control.

As haul roads shift and conditions evolve throughout the day, AVA provides supervisors and dispatchers with real-time insights that enhance shift-to-shift performance.

AVA supports mining productivity by enabling:

- Cycle time optimization for load–haul–dump workflows.

- Fleet balancing, ensuring equipment is assigned where it creates the most value.

- Short interval control enables teams to identify and correct bottlenecks during shifts.

- Operator performance insights, promoting safer and more consistent work.

- Automated KPIs for queue time, travel time, shovel utilization and payload flow.

Technologies for Smarter Mining

To complement our mining machine connectivity solutions, we offer Teledyne’s suite of mining-focused tools. These technologies include:

- LiDAR scanning for precise terrain mapping and slope monitoring.

- Thermal imaging for early equipment health detection.

- Air quality monitoring to help maintain healthy and compliant work environments.

Included in our offerings is the Teledyne TLS-M3 scanner, an IP56-rated system designed to support long-term monitoring in mine, dam and marine applications. This robust, highly efficient scanner provides the range and real-time data your operations need.

Reach out Today

Our team invests time in understanding each site’s unique needs, then matching those needs with adaptable technologies that grow with you. If you are ready for stronger, smarter mining connectivity, contact Intermountain Technologies to discuss upgrading your mining communication network.