Imaging and Connectivity for Quarry Operations

Intermountain Technologies helps quarries operate with greater confidence by delivering technology that enhances safety and improves production insight by strengthening communication and data collection across every acre of your site. Our approach centers on long-term partnerships and value-driven solutions that support your team and prepare your operation for the future.

With innovations from Teledyne and Rajant, we provide quarry connectivity solutions, thermal imaging systems and continuous condition monitoring tools that deliver actionable data. The result is a more efficient operation.

Advanced Thermal Imaging

Modern quarries rely on dependable insight to keep crews safe and equipment running. Intermountain Technologies offers thermal imaging platforms, which help teams detect early signs of wear, avoid potential hazards, and maintain equipment health with confidence.

Our quarry thermal imaging solutions offer:

- Crusher bearing thermal monitoring: Heat patterns reveal early signs of stress and imbalance, giving maintenance teams time to act before production slows.

- Conveyor bearing temperature monitoring: Thermal data helps identify misalignment and lubrication issues, ensuring continuous material flow.

- High-value asset protection: Fixed thermal cameras monitor engines, motors, hydraulic systems and electrical components so operators can respond proactively.

By integrating thermal imaging into daily operations, quarries gain the clarity needed to reduce unplanned maintenance and support safer work environments.

Precision Tools for Mapping and Environmental Insight

Equipment performance is only one part of a successful quarry. Understanding changing terrain, maintaining clean air and accurately planning extraction activities are equally critical. IMT supports these needs with a range of Teledyne technologies built for rugged industrial settings:

- 3D geospatial mapping: Rugged LiDAR systems provide detailed, real-time site models for improved haul road management, high wall assessments and long-term planning.

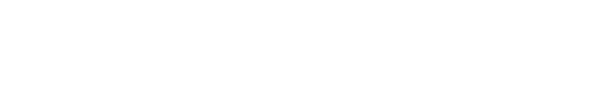

- Air quality monitoring: ACES® systems watch for dust, particulates, CO₂ and other airborne indicators, helping maintain healthier operator cabins and compliance-friendly worksites.

- Digital prospecting: Through the MUSES platform and the DESIS hyperspectral imager, operators gain access to unseen data that reveals material composition and helps uncover valuable deposits.

Each tool empowers teams to make informed decisions based on real-time site conditions.

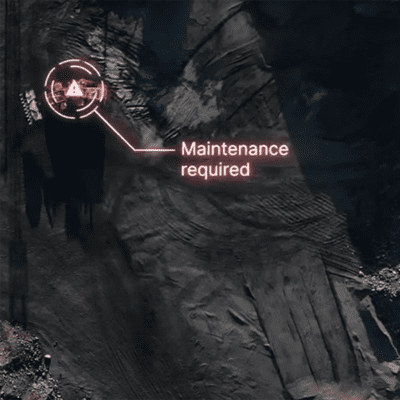

AVA Software Solutions for Quarry Cycle Optimization

To help quarries get the most out of their equipment and daily production cycles, IMT offers AVA software — an advanced analytics platform designed to optimize haul cycles, improve fleet utilization and support short interval control.

This solution brings together live machine data, wireless connectivity and operator inputs so that quarry teams can identify bottlenecks and quickly correct inefficiencies.

Built for high-output quarry environments, AVA enables:

- Fleet optimization for quarries, helping teams rebalance assets and reduce idle time.

- Real-time quarry cycle optimization, identifying delays at loaders, crushers and dumpsites.

- Short interval control workflows, giving supervisors actionable insights during the shift — not after.

- Automated KPIs for haul truck performance, cycle consistency, queue times and operator efficiency.

- Improved communication between dispatch, supervisors and equipment operators through a centralized, intuitive dashboard.

Wireless Connectivity Built for the Quarry Environment

Consistent communication is the backbone of a productive quarry. Intermountain Technologies offers wireless systems powered by Rajant’s mobile, self-optimizing mesh technology. This technology is purpose-built for large, dynamic and often obstructed environments like quarries.

Our quarry connectivity solutions deliver:

- Fully mobile networking: Moving equipment maintains real-time connectivity without the handoff issues common in traditional networks.

- Rugged BreadCrumb® nodes: These compact devices create a private wireless backbone for video, telemetry, automation and sitewide communication.

- Autonomous network routing: Rajant’s InstaMesh® technology ensures the network adapts instantly to terrain, equipment movement and changing site conditions.

This level of resilience supports everything from remote camera feeds to equipment health sensors, giving you a detailed view of quarry performance.

Contact Us to Learn More

Our team works closely with quarry operators to understand daily workflows and the requirements that come with high-output production. We offer ongoing consulting, remote monitoring assistance and a commitment to helping sites adopt new technology smoothly. Contact us today with your questions and let’s start enhancing your operational efficiency.